flat knitting machine HF-350

The single-head double-system roller model can be equipped with a comb device and adopts the Hengqiang integrated control system.

The hardware is equipped with a motor connecting rod. Compared with the magnet-seat type connecting rod, the large rod wear is eliminated, the single-port intermediate rotation can be realized, the rotation distance is shortened, the swing control position is more accurate, and the ultra-small head design can be improved efficiency by about 20%. The machine realizes multi-segments stitch knitting in the same line with the equipment of stitch motor with dynamic stitch function.

These series uses digital technology to achieve the patterns of weaving, pointel, tuck, tight tuck, apparent shape, hidden shape, intarsia, float less intarsia and other irregular structure patterns.

Product specification

| Gauge | 5G、5/7G、12G、14G、16G | |

| Knittig width | 45 Inches | 52 Inches |

| Knitting speed | Max speed 1.6 m / sec, 32 segment programmable speed | |

| Stitch density | 32 segments of electronic control, the use of subdivision technology, adjustable range:0-650, more accurate control of the length of fabric | |

| Knitting system | Single carriage with double systems | |

| Rib transfer | Both front and back, not affecting by the carriage direction, separately knitting | |

| Sinker system | The stepping motor can adjust the movable settling plate, and can be adjusted according to different fabrics to achieve a pluarity of collecting and putting effects. | |

| Actuator | 8 section electronic needle selectors | |

| Comb device | The comb device with releasing pinciple,can effectively realize yarn hanging and sloughing function | |

| Roller device | Main roller and the comb,the 32 section of automatic control,subsection adjustment | |

| Color changing device | 8 set of yarn feeder configuration in the right and left sides of the guide rail | 8+4 set of yarn feeder configuration in the right and left sides of the guide rail |

| Protection | Automatic stopping device if yarn broke, yarn knot, batching, striking, completion,overload, designated starting and stopping, program error | |

| Driving system | Belt drive,AC servo motor control | |

| Motor connecting rod | The connecting rod is driven by the machinery electron motor,in a result to achieve more accurate direction changing | |

| Safefy device | The whole machine cover to reduce noise and dust,the protecting cover is equipped with stopping sensor,emergency stopping,power off device | |

| Data imput | Through the U disk, computer connection for direct imput of data | |

| Lauguage choice | Multi-language version: support Chinese, English, Arabia and other languages,but also according to customer needs to increase the required language | |

| Size | L*W*H: 2180X850X1870 mm | L*W*H: 2530X850X1870 mm |

| Weight | 1000kg | 1000kg |

| Power | Voltage: AC 200V; Frequency: 50HZ; Power: 1.0KW | Voltage: AC 220V; Frequency: 50HZ; Power: 1.5KW |

Detail display

|

|

|

||

|

Stitch Motor

|

Display Screen

|

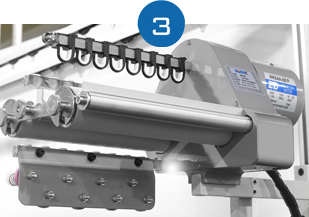

Yarn Storage

|

||

|

With dynamic stitch function, using high speed stepping motor, multi-stitch function can be achieved in one line. |

It adopts industry LCD displayer with graphic touch control, multi-color. The data of knitting amount, time, speed, roller, stitch, yarn feeder, etc. is all can be seen on the screen. |

Positive Yarn Storage could reduce resistance while the yarn is moving, is especially suitable for fabric with lack of elasticity and brittleness such as cashmere yarn, rabbit hair yarn, to make the fabric even and improve knitting efficiency. |

||

|

|

|

|

|

|

|

|

|

||

|

Servo Motor

|

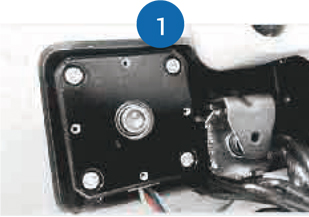

Motor Connecting Rod

|

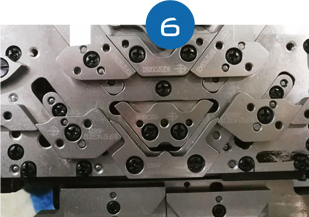

Tight Tuck

|

||

|

Using CANI communication control, can achieve the fast return and the diversion of the machine head, accurate positioning, smooth commutation. |

The connecting rod is driven by the machinery electron motor, in a result to achieve more accurate direction changing |

To achieve different tightness of tight tuck, the cam is controlled by machinery electron motor, and range from 0-90. |