flat knitting machine HF-260

Single carriage with double systems or triple systems. This model uses Hengqiang A8 integrated machine system which is based on the Cortex-A8 core of ARM, and the main frequency is improved to 600MHz, the RAM is increased to 256M for more smooth operation; About hardware, the temperature detection, multi-path power failure detection, and short circuit protection are added; and improvement has been made in anti-static electricity, the pin failure rate has been greatly decreased.

The hardware is equipped with a motor connecting rod. Compared with the magnet-seat type connecting rod, the large rod wear is eliminated, the single-port intermediate rotation can be realized, the rotation distance is shortened, the swing control position is more accurate, and the ultra-small head design can be improved efficiency by about 20%. The machine realizes multi-segments stitch knitting in the same line with the equipment of stitch motor with dynamic stitch function.

These series uses digital technology to achieve the patterns of weaving, pointel, tuck, tight tuck, apparent shape, hidden shape, intarsia, floatless intarsia and other irregular structure patterns. (Note: Memory size can be increased according to customers’ need)

Product specification

| Gauge | 14G | ||||||||||||||||||||||||||

| Needle bed width | 36/52/72 Inches | ||||||||||||||||||||||||||

| Knitting system | Single carriage with double/triple systems | ||||||||||||||||||||||||||

| Speed | Max speed 1.6 m / sec | ||||||||||||||||||||||||||

| Racking | Motor drive, maximum 2 inches | ||||||||||||||||||||||||||

| Needle actuator | 8 section electronic needle actuator | ||||||||||||||||||||||||||

| Sinker system | Latest sinker syestem, drived by stepping motors, which can meet the various local weaves of the upper | ||||||||||||||||||||||||||

| Protection | Automatic stopping device if yarn broke, yarn knot, batching, striking, completion,overload, designated starting and stopping, program error | ||||||||||||||||||||||||||

| Yarn forwar device | Yarn feeder and yarn storage device(optional),accurate control of yarn tension,to ensure the quality of the overall quality of the fabric | ||||||||||||||||||||||||||

| Safety device | The whole machine cover reduces noise and dust,the protecting cover is equipped with stopping sensor,emergency stopping,power off device | ||||||||||||||||||||||||||

| Roller device | High-order Roller,subsection adjustment | ||||||||||||||||||||||||||

| Motor connecting rod | The connecting rod is driven by the machinery electron motor,in a result to achieve more accurate direction changing | ||||||||||||||||||||||||||

| Tight tuck | To achieve different tightness of tight tuck,the functioned cam is controlled by machinery electron motor | ||||||||||||||||||||||||||

| Size and weight | Size:L*W*H 2600*940*1900/2970*940*2010/3380*940*2010mm; Weight:1100/1350kg | ||||||||||||||||||||||||||

| Power | Voltage:AC 220V /380V;Frequency: 50HZ/60HZ; Power:1.5KW/2.0KW | ||||||||||||||||||||||||||

Detail display

|

|

|

||

|

Stitch Motor

|

Display Screen

|

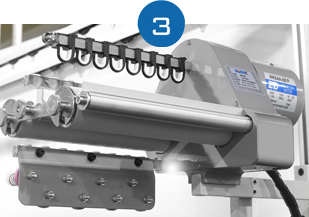

Yarn Storage

|

||

|

With dynamic stitch function, using high speed stepping motor, multi-stitch function can be achieved in one line. |

It adopts industry LCD displayer with graphic touch control, multi-color. The data of knitting amount, time, speed, roller, stitch, yarn feeder, etc. is all can be seen on the screen. |

Positive Yarn Storage could reduce resistance while the yarn is moving, is especially suitable for fabric with lack of elasticity and brittleness such as cashmere yarn, rabbit hair yarn, to make the fabric even and improve knitting efficiency. |

||

|

|

|

|

|

|

|

|

|

||

|

Servo Motor

|

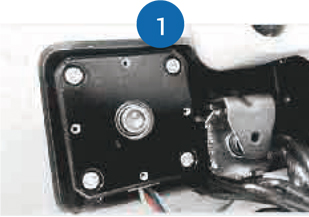

Motor Connecting Rod

|

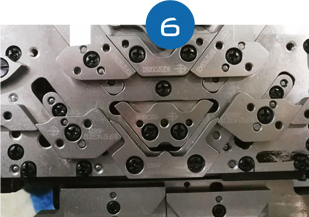

Tight Tuck

|

||

|

Using CANI communication control, can achieve the fast return and the diversion of the machine head, accurate positioning, smooth commutation. |

The connecting rod is driven by the machinery electron motor, in a result to achieve more accurate direction changing |

To achieve different tightness of tight tuck, the cam is controlled by machinery electron motor, and range from 0-90. |